How to Replace an Improper TPRV Discharge Pipe

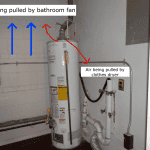

The TPRV is a safety device that prevents your water heater from turning into a rocket and propelling through your roof. Given its importance, we are surprised at the number of discharge pipes installed improperly. That’s why we wrote this blog detailing how to replace a TPRV discharge pipe.

Many things can be wrong with the discharge pipe. You can find the general rules for a discharge pipe at the end of this post. If you are confident with your repair skills, it’s an easy task to replace them yourself.

Materials:

- 8ft of CPVC pipe,

- CPVC primer and CPVC cement(comes in a pack of a purple can and an orange can),

- CPVC to 3/4″ copper male union,

- Thread Seal Plumbing Tape.

(Total cost about $20)

Tools:

- Adjustable wrench,

- plastic pipe cutter,

- measuring tape,

- possibly a saw to cut the pipe first

(Total cost about $30)

Steps To Replace TPRV Discharge Pipe:

1. First, make sure you turn off the power supply, whether it’s a breaker, a gas valve, or an oil valve.

2. Next, turn off the water at the main water shut-off valve.

3. Now would be a good time to Flush Your Water Heater.

4. Remove the improper discharge pipe.

5. Measure from the bottom of the TPR valve to the ground and subtract 4″. The pipe can not be more than 6″ off the ground.

6. Cut your pipe to the appropriate size.

7. Follow the instructions on the CPVC cement cans and connect the union to the pipe you just cut.

8. Apply the thread seal to the union.

9. Install the assembly into the TPR valve.

10. Some TPR valves are at the top of the tank. In this case, you will simply need to make one extra measurement, one extra cut, and a 90-degree angle to the pipe assembly. Do not glue the vertical pipe into the horizontal pipe until after you install the horizontal pipe into the valve!

11. Turn on the main water shut-off valve and turn the breaker back on.

Here are the requirements for TPRV discharge pipes

- Be constructed of an approved material, such as CPVC, copper, polyethylene, galvanized steel, polypropylene, or stainless steel. PVC and other non-approved plastics should not be used since they can easily melt.

- Not be smaller than the diameter of the outlet of the valve it serves (usually no smaller than 3/4″).

- Not reduced in size from the valve to the air gap (point of discharge).

- be as short and as straight as possible so as to avoid undue stress on the valve.

- be installed so as to drain by the flow of gravity.

- not be trapped, since standing water may become contaminated and backflow into the potable water.

- discharge to a floor drain, to an indirect waste receptor, or to the outdoors.

- not be directly connected to the drainage system to prevent backflow of potentially contaminating the potable water.

- discharge through a visible air gap in the same room as the water-heating appliance.

- be first piped to an indirect waste receptor such as a bucket through an air gap located in a heated area when discharging to the outdoors in areas subject to freezing, since freezing water could block the pipe.

- not terminate more than 6 inches (152 mm) above the floor or waste receptor.

- discharge in a manner that could not cause scalding; and

- discharge in a manner that could not cause structural or property damage; and

- discharge to a termination point that is readily observable by occupants, because discharge indicates that something is wrong, and to prevent unobserved termination capping.

- be piped independently of other equipment drains, water heater pans, or relief valve discharge piping to the point of discharge.

- not have valves anywhere.

- not have tee fittings.

- and not have a threaded connection at the end of the pipe so as to avoid capping.

Good job!

As an Amazon Associate I earn from qualifying purchases. So I provide you with you relevant knowledge and products to make extra money 🙂